Introduction

Toasters have become an indispensable kitchen appliance for toasting bread and other baked goods. One fundamental aspect of their functionality is their ability to generate heat energy. Understanding how a toaster produces heat is key to appreciating the process of toasting. In this guide, we will explore the mechanisms behind heat production in toasters, examining the various components and processes involved in generating the necessary heat energy for toasting.

How does a toaster produce heat energy?

I. Electrical Power Supply

-

Plug into Power Source:

- To begin the heat production process, the toaster must be securely plugged into a power outlet. This establishes the electrical connection necessary for the toaster to receive electrical power.

-

Electrical Circuitry:

- Once plugged in, the electrical circuitry within the toaster enables the flow of electric current from the power source to the internal components responsible for generating heat.

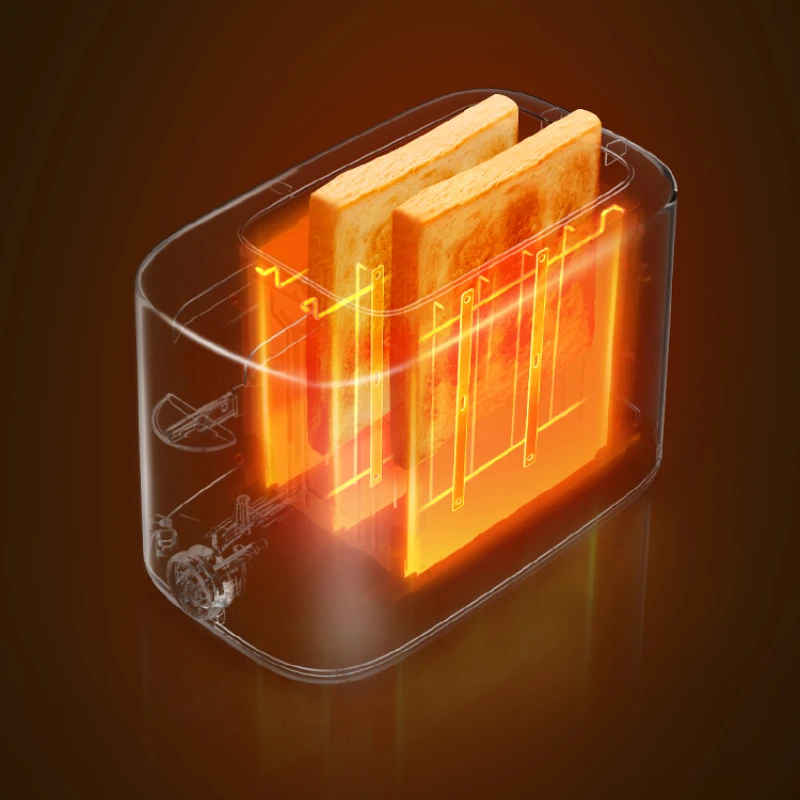

II. Heating Elements

-

Composition of Heating Elements:

- The heating elements are critical components within the toaster that produce and distribute heat energy. They are typically made of a high resistance alloy known as nichrome wire, which is designed to withstand high temperatures.

-

Electrical Resistance:

- The nichrome wire in the heating elements is specifically chosen for its high electrical resistance. When an electric current passes through the wire, the high resistance leads to the generation of heat.

-

Encasing the Heating Elements:

- The heating elements are encased within a protective insulating material, often mica, which helps to safeguard against electrical shocks and ensures that the heat generated is directed towards toasting.

III. Electric Current and Heat Generation

-

Conversion of Electrical Energy:

- As electric current passes through the nichrome wire heating elements, it encounters resistance. This resistance converts electrical energy into heat energy according to Joule’s Law, which states that heat is produced when an electric current flows through a resister.

-

Electric Resistance and Heat Production:

- The high resistance of the nichrome wire results in a considerable amount of heat generation. It causes the wire itself to become hot, thereby producing the heat energy required for toasting.

-

Heat Transfer to Surroundings:

- Once generated, the heat energy in the heating elements is transferred to the surrounding areas within the toaster through conduction, convection, and radiation, allowing for efficient toasting.

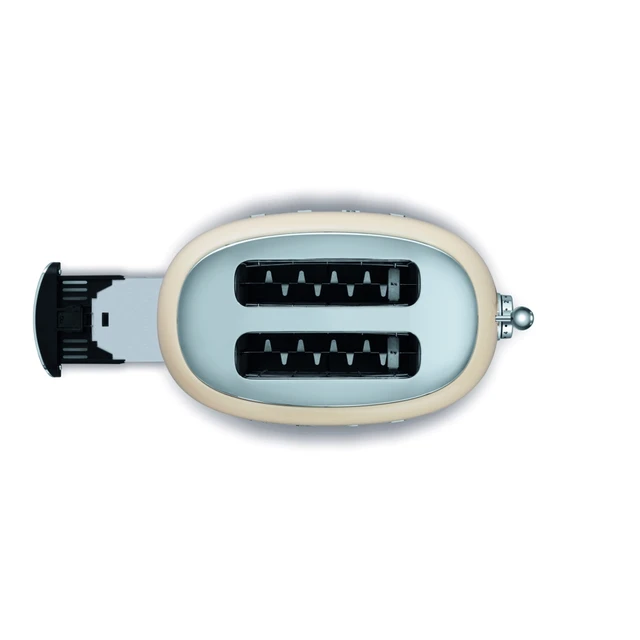

IV. Toasting Chamber and Slot Design

-

Efficient Heat Distribution:

- The design of the toasting chamber and slots in the toaster is crucial for ensuring an even distribution of heat. Well-designed toasters allow hot air circulation, facilitating consistent toasting of bread slices.

-

Reflective Interior:

- To maximize heat distribution, the interiors of toasting chambers are often coated with reflective materials, such as aluminum or stainless steel. These materials reflect heat back towards the bread slices, promoting even browning.

-

Insulated Structure:

- To minimize heat loss, toaster exteriors are typically built with insulating materials, ensuring that the heat energy produced in the heating elements is directed towards the toasting chamber and bread slices rather than being wasted.

V. Toasting Process and Heat Energy

-

Initiating the Toasting Process:

- When the user activates the toaster by depressing the lever or pressing a button, electrical power flows through the heating elements, initiating the toasting process.

-

Heat Radiance and Transfer:

- As the heating elements become hot, they radiate heat energy into the surroundings. This radiant heat is transferred to the bread slices or other baked goods placed in the toaster’s slots, initiating the toasting process.

-

Moisture Removal and Browning:

- The heat energy absorbed by the bread slices causes moisture evaporation and initiates the Maillard reaction, resulting in the browning and flavor development associated with toasting.

VI. Safety Precautions

-

Automatic Shut-Off Mechanisms:

- To prevent overheating and potential fire hazards, many toasters incorporate automatic shut-off mechanisms that deactivate the heating elements after a specific time or when the internal temperature reaches a certain threshold.

-

Insulated Exteriors:

- Toaster exteriors are designed to stay cool to the touch during operation, thanks to effective insulation. This minimizes the risk of burns or accidents caused by accidental contact with the heated surfaces.

-

Fire-Resistant Materials:

- The materials used in toaster construction, such as insulating plastics and fire-resistant coatings, are carefully chosen to minimize the risk of fire accidents and ensure the safe operation of the toaster.

VII. Maintenance and Cleaning

-

Regular Cleaning:

- To maintain optimal heat production and toasting performance, it is necessary to clean the toaster regularly. Removing crumbs and debris from the crumb tray, slots, and heating elements prevents buildup and potential fire hazards.

-

Safe Handling:

- When cleaning the toaster, always follow the manufacturer’s instructions to ensure proper handling and safe maintenance. Unplug the toaster and allow it to cool before cleaning to avoid electrical shocks or burns.

IX. Innovations and Advancements

-

Infrared Toasting Technology:

- Some modern toasters incorporate infrared toasting technology, which utilizes radiant heat to toast bread more efficiently. Infrared elements emit shorter, more intense waves of energy, resulting in faster and more consistent toasting.

-

Quartz Heating Elements:

- Quartz heating elements are a newer development in toaster technology. These elements heat up quickly and provide more precise control over the toasting process. They offer energy efficiency and faster heating compared to traditional nichrome wire heating elements.

-

Digital Heat Sensors:

- Advanced toasters may feature digital heat sensors that monitor the temperature within the toasting chamber. These sensors ensure that the desired level of browning is achieved and prevent over-toasting by adjusting the toasting time or heat output automatically.

-

Multiple Toasting Options:

- Some toasters now offer multiple toasting options, allowing users to select specific settings for bagels, English muffins, or frozen bread products. These options adjust the heat output and toasting time accordingly, resulting in perfectly toasted items.

-

Countdown Timers and LCD Displays:

- To enhance convenience and precision, many toasters now come equipped with countdown timers and LCD displays. These features provide real-time information on the remaining toasting time and allow users to monitor the toasting process more accurately.

X. Energy Efficiency

-

Quick Heat-Up Time:

- To improve energy efficiency, modern toasters are designed to reach the desired toasting temperature rapidly. This reduces the amount of time and energy required to produce the necessary heat for toasting, resulting in lower energy consumption.

-

Auto-Shutoff Features:

- Automatic shut-off mechanisms found in many toasters are not only safety features but also contribute to energy efficiency. These mechanisms prevent the toaster from operating longer than necessary, saving energy and reducing the risk of overheating.

-

Toasting Slot Adjustments:

- Some toasters offer the flexibility to use fewer slots when toasting fewer items, allowing users to conserve energy by minimizing heat loss. This feature is particularly useful for households or individuals toasting smaller quantities of bread.

VIII. Conclusion

The production of heat energy is a crucial component of a toaster’s functionality. Through the efficient conversion of electrical energy using heating elements, toasters generate heat that is then transferred to the bread slices within the toasting chamber. The design of the toasting chamber, reflective interiors, and insulated exteriors further optimize heat distribution for consistent and even toasting. Compliance with safety precautions and regular maintenance are essential for safe and efficient operation. Understanding the process of heat production in toasters facilitates a greater appreciation of the engineering and design behind this everyday kitchen appliance and promotes responsible and enjoyable toasting experiences.