Introduction:

Blenders are indispensable kitchen tools, whether you’re crafting smoothies, soups, or sauces. But what happens when your go-to appliance breaks down? Encountering a broken blender can be frustrating, but understanding how to diagnose and fix common issues can save you a lot of time and money. This comprehensive guide will walk you through troubleshooting steps and solutions for handling a malfunctioning blender. Read on to discover how you can efficiently tackle the problem and get back to blending in no time.

How to Handle a Broken Blender?

Blender Troubles, Efficient Fixes

Identifying the Problem

Before diving into repairs, the first step is accurately identifying what’s wrong with your blender. Different symptoms point to different issues, and understanding these can guide you in finding the right solution.

Blender Won’t Turn On

If your blender refuses to start, it could be due to a simple power issue or something more complex. Begin by checking if the blender is plugged in securely. Inspect the power cord for any visible damage, and ensure that the outlet is functioning properly by testing it with another appliance.

Unusual Noises

Grinding, clanking, or other unusual noises coming from your blender often indicate mechanical problems. Such noises might result from worn-out gears, a damaged blade assembly, or misaligned components. Take note of when the noise occurs (e.g., immediately upon starting, during blending, or only with certain ingredients) to better diagnose the issue.

Leaking from the Base

Leaking from the Base

Leaks from the base of the blender are typically due to faulty seals or loose components. Inspect the jar for cracks and check the gasket or seal for wear. Ensure all parts are assembled correctly, and nothing is cross-threaded or improperly seated.

Burnt Smell or Smoke

If you notice a burnt smell or see smoke, immediately unplug the blender to prevent further damage or risk of fire. This issue is often caused by an overheating motor or electrical short. Allow the blender to cool down and inspect it for any burnt components or wires.

Performing Basic Troubleshooting

Once you’ve identified the problem, basic troubleshooting steps can often resolve the issue. These steps are easy to perform and can fix many common blender problems.

Resetting the Blender

Some blenders have a reset function that can resolve issues caused by overheating or power surges. If your blender model has a reset button, unplug the appliance, press and hold the reset button for a few seconds, then plug it back in and test it.

Cleaning and Reassembling

Accumulated debris and improperly assembled parts can cause various issues. Disassemble the blender and clean all components thoroughly. Ensure each part is dry and reassemble the blender correctly, paying attention to the alignment and secure fitting of each component.

Inspecting the Blades

Blunt or damaged blades significantly affect blender performance. Carefully examine the blades for any signs of wear or damage. If needed, replace the blades to restore proper functionality.

Repairing Electrical Issues

Repairing Electrical Issues

Electrical problems with blenders are more complex and often require careful handling. If you’re comfortable working with electrical components, follow these steps:

Testing the Power Cord

Use a multimeter to check for continuity in the power cord. If the multimeter doesn’t show continuity, you might need to replace the power cord. Ensure you purchase a cord that matches your blender’s specifications.

Checking Internal Connections

Unplug the blender and disassemble the base to access internal wiring. Look for any loose or disconnected wires and reattach them securely. Check the condition of the wires and connectors, replacing any that appear burnt or damaged.

Examining the Fuse

Some blenders have an internal fuse that protects against electrical overload. Check your blender’s manual to locate the fuse and test it with a multimeter. If the fuse is blown, replace it with one of the same rating.

Fixing Mechanical Problems

Mechanical issues often involve broken or worn-out parts that need replacement. Here’s how to address common mechanical problems:

Replacing the Drive Coupling

The drive coupling connects the motor to the blade assembly. Over time, this part can wear out, causing a decrease in performance or complete failure to blend. Purchase a replacement drive coupling specific to your blender model and follow the instructions for installation.

Gasket or Seal Replacement

Leaky blenders often need new gaskets or seals. Identify the type of gasket or seal required for your blender model and replace it accordingly. Ensure the new seal is fitted securely to prevent future leaks.

Blade Assembly Replacement

If the blade assembly is damaged beyond repair, replace it with a new one. Ensure compatibility with your blender model and carefully follow the replacement steps to install the new assembly correctly.

When to Seek Professional Help

When to Seek Professional Help

While many blender issues can be resolved at home, some situations require professional assistance. Knowing when to seek help can prevent further damage and ensure safety.

Complex Electrical Issues

If you’re not comfortable handling electrical repairs or if initial troubleshooting doesn’t resolve the issue, it’s best to consult a professional. Electrical components can be dangerous, and improper handling may cause further damage or injury.

Persistent Mechanical Problems

If replacing common parts like the blades, coupling, or seals doesn’t fix the problem, the issue might be deeper within the motor or internal mechanisms. Professional repair services can diagnose and fix these complex mechanical problems.

Under Warranty

If your blender is still under warranty, contact the manufacturer for repairs or replacements. Attempting to fix the blender yourself might void the warranty, so follow the appropriate channels for service.

Preventive Measures

Taking preventive measures can help extend the lifespan of your blender and minimize breakdowns.

Regular Maintenance

Perform regular maintenance, including thorough cleaning after each use and periodic inspections of blades and seals. Routine maintenance helps catch potential issues early, allowing for timely intervention.

Avoid Overloading

Overloading the blender puts unnecessary strain on the motor and blades. Follow the manufacturer’s recommended capacity limits and blend in smaller batches if needed.

Proper Storage

Store your blender in a dry, safe location to prevent damage to components. Ensure the cord is wrapped neatly and the blender is placed in a stable position to avoid falls or impacts.

Cost Considerations

Understanding the costs associated with repairing versus replacing your blender can guide your decision-making process.

Cost of Parts

Research the cost of replacement parts for your blender model before proceeding with repairs. In some cases, the cost of multiple parts may approach the price of a new blender, making replacement a more economical choice.

Labor Costs

If professional repair services are needed, inquire about labor costs upfront. Weigh these costs against the price of a new blender to assess the most cost-effective option.

Choosing a New Blender

Choosing a New Blender

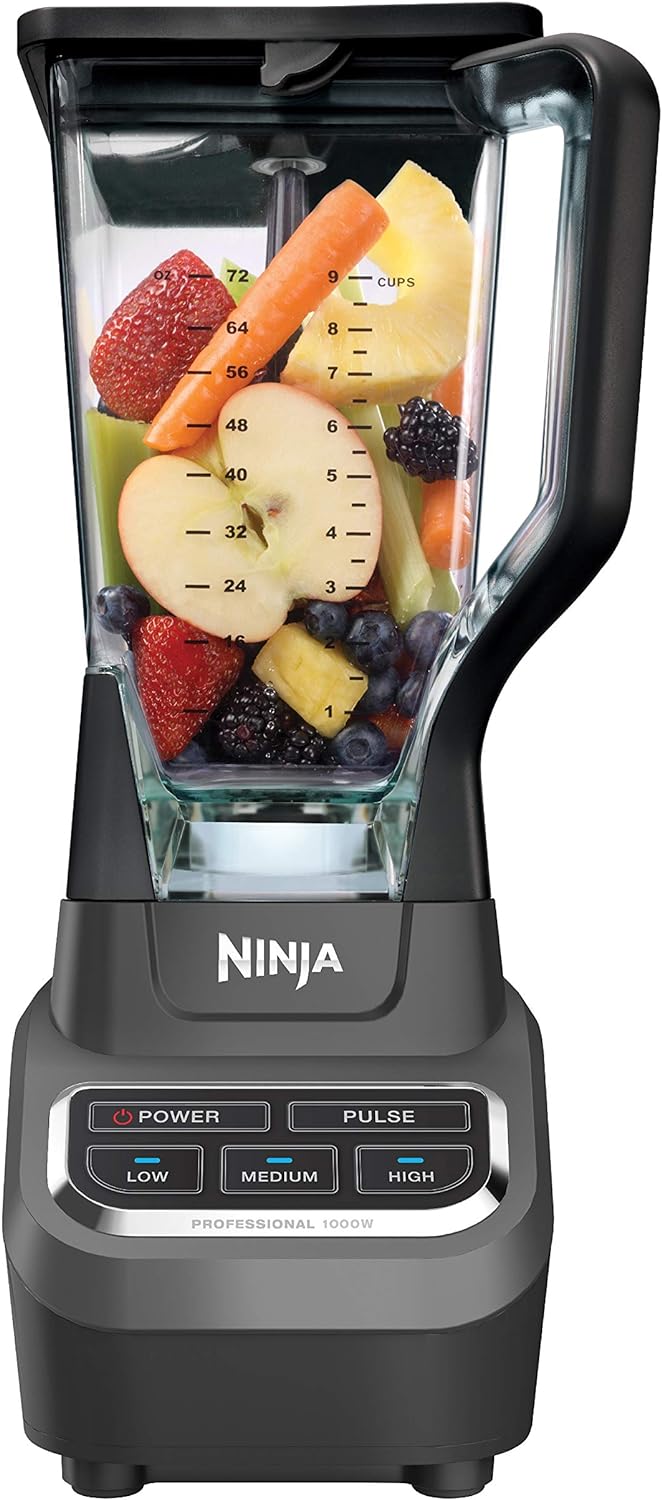

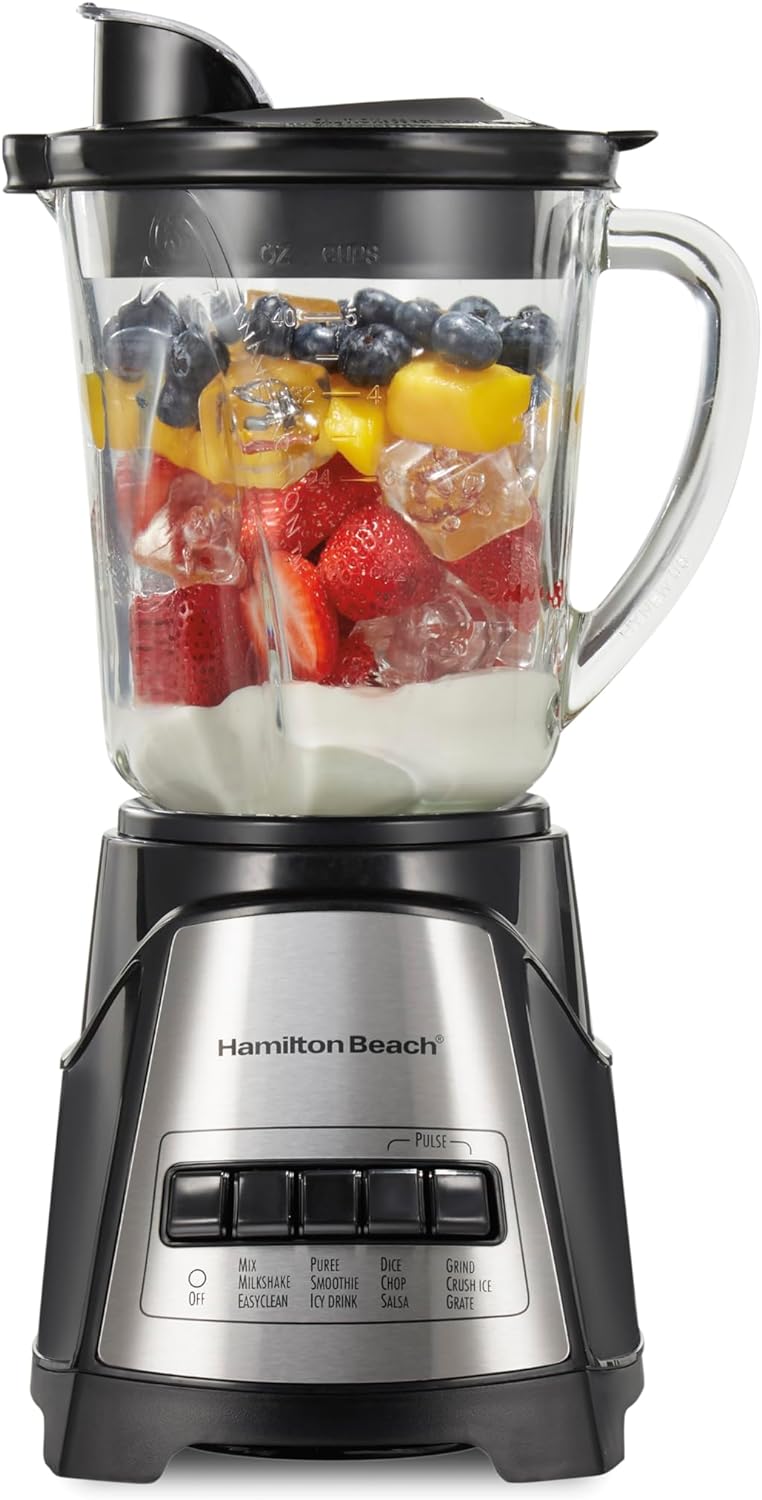

If repairing your blender isn’t viable, choosing a new one involves considering several factors to ensure you invest in a durable, high-performance appliance.

Blender Type

Decide on the type of blender that best suits your needs, whether it’s a high-performance blender for versatile tasks, a personal blender for single servings, or an immersion blender for specific applications.

Key Features

Look for essential features such as variable speed settings, pulse function, self-cleaning capability, and durability of materials. These features enhance the functionality and longevity of the blender.

Budget

Determine your budget and explore options within that range. High-end models like Vitamix or Blendtec offer premium features and durability, while mid-range brands like Ninja provide excellent performance at a lower price point.

Conclusion:

Getting Back to Blending

Encountering a broken blender doesn’t have to spell disaster. By accurately diagnosing the issue, performing basic troubleshooting, and knowing when to seek professional help, you can effectively handle most common blender problems. Taking preventive measures and understanding cost considerations further aid in maintaining a functional blender or choosing a new one if necessary. With these tips, you can efficiently address any blender issues and continue enjoying your favorite blended creations without prolonged disruption.